In 1972, since HOTAI developed its own TPR material, we simultaneously improve the mold and injection molding machine to make this technology can be utilized in the shoe sole manufacturer. This material and molding technology continues to be widely used in the industry today.

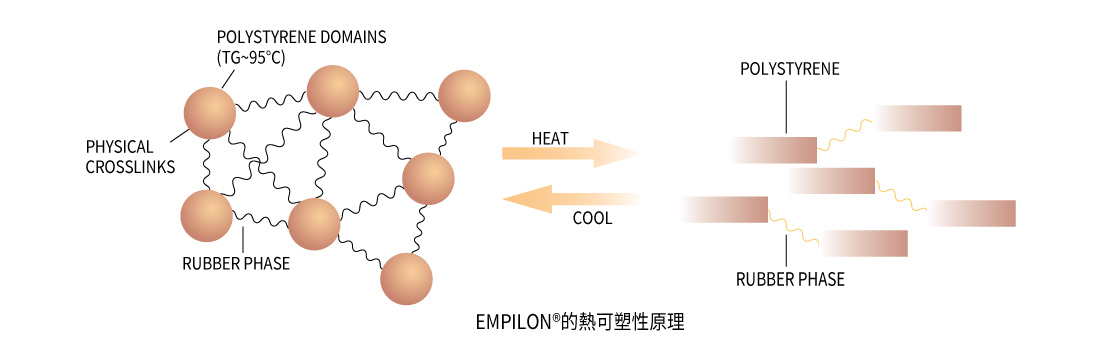

In order to respond to the fast-growing international market and create material which is more advanced and diverse than TPR. In 1986, we began to develop and use reference formulation technology to produce HTPR (Hydrogenated Thermal Plastic Rubber), and we launched our own brand as EMPILON®